Driving Quality. Delivering Precision.

At LEDVORE, we support the automotive industry with comprehensive project management, resource deployment, and manufacturing solutions that accelerate product development and improve operational efficiency. We help automotive OEMs, Tier 1 & Tier 2 suppliers achieve faster delivery cycles, cost-effective production, and quality excellence.

Our Capabilities

Product Design & Analysis

We help you bring your automotive product ideas to life with precise, industry-compliant design and comprehensive engineering analysis. Our services include Geometric Dimensioning & Tolerancing (GD&T), detailed 2D drawings, Design Failure Mode and Effects Analysis (DFMEA), Computational Fluid Dynamics (CFD), structural analysis, and vibration testing.

How It Helps:

Our design solutions accelerate development timelines, improve part reliability, and reduce costly design iterations.

By applying GD&T and detailed 2D drawings, we ensure that parts are manufacturable with tight tolerances and minimal variation.

DFMEA support helps you predict and mitigate design risks early in the development cycle, saving time and avoiding expensive late-stage failures.

Through CFD, structural, and vibration analysis, we validate real-world performance, ensuring parts meet safety, durability, and functional expectations.

Whether you’re launching a new product or enhancing an existing one, we ensure your design meets global performance and quality standards on time and within budget.

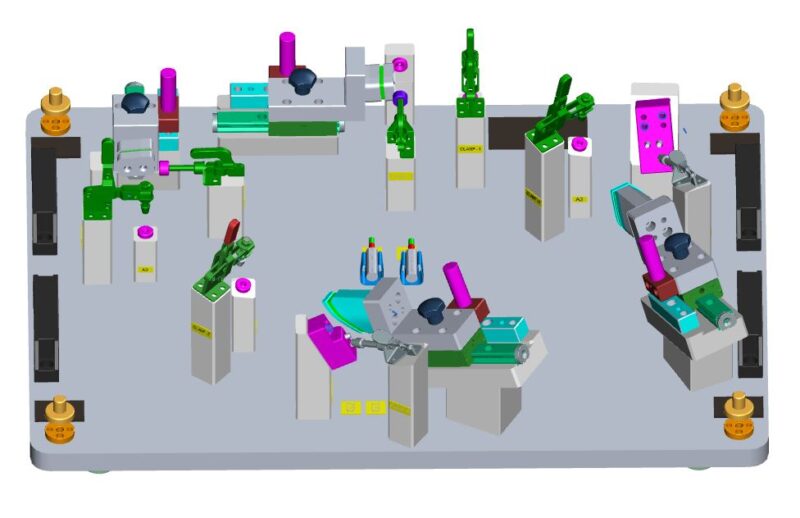

Checking Fixtures & Tooling Solutions

We create high-precision checking fixtures that ensure your components fit, function, and meet quality standards.

How it helps:

Our fixtures streamline inspection processes, improve assembly accuracy, and reduce production errors. This saves time, lowers inspection costs, and supports flawless part integration across your automotive assembly lines.

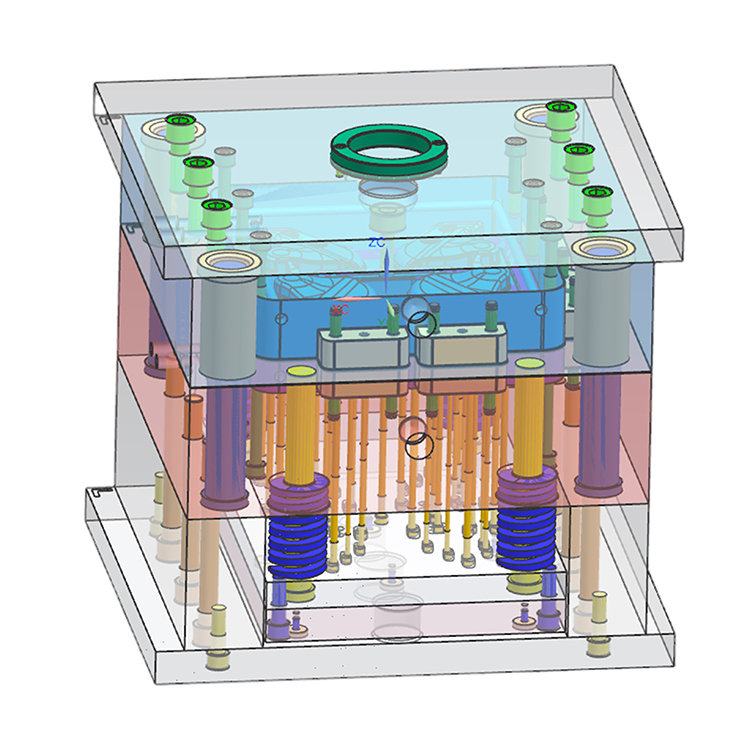

Plastic Moulding Solutions

Our plastic moulding solutions deliver durable, high-quality components tailored to the demanding needs of automotive manufacturing.

How it helps:

We help you produce lightweight, cost-effective, and precision-moulded parts that improve vehicle performance and meet tight production deadlines. From prototyping to high-volume production, we ensure consistency at every step.

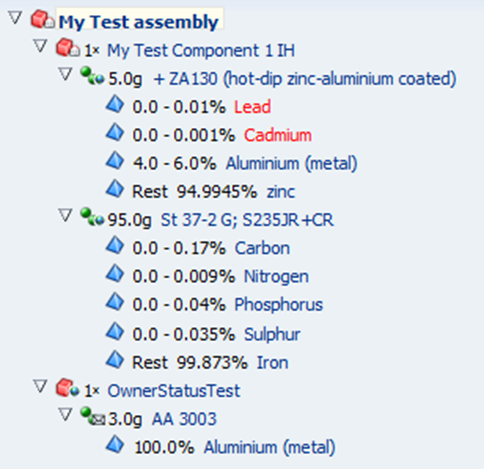

IMDS (International Material Data System) Support

We provide full IMDS submission support to help you meet global automotive material reporting requirements.

How it helps:

Navigating material compliance can be complex. We simplify the process by managing your IMDS data and documentation, ensuring faster approvals and helping you maintain supply chain transparency with minimal effort.

Part Sorting & Quality Inspection

We offer on-site and off-site part sorting, visual checks, and dimensional inspections to guarantee defect-free supply.

How it helps:

Our quick-response sorting services protect your production lines from non-conforming parts, reduce downtime, and improve customer satisfaction by ensuring only the right parts reach your assembly.

Quality Documentation: PPAP, Testing & Validation

We support your quality teams with PPAP documentation, product testing, and performance validation.

How it helps:

We help you achieve faster approvals, reduce quality risks, and meet stringent automotive standards. With our testing and validation services, you can be confident that your parts will perform as expected in real-world conditions.

Why LEDVORE for Automotive?

~Global project management expertise

~Cost-effective, agile solutions

~Strong Automotive domain knowledge

~Quick turnaround with responsive support

~Commitment to international quality standards

We help our automotive clients optimize their production process, improve quality control, and accelerate project timelines with reliable support across Europe, America, and Asia.